- Home

- Startup news

- Because farmers need certainty, B-COS engineers predictable protection

Because farmers need certainty, B-COS engineers predictable protection

What does it take to convince a farmer to use alternatives to synthetic chemical pesticides? A biological, sustainable alternative that works as reliably as the chemical it's meant to replace. B-COS, a new startup emerging from Ghent University, is building exactly that. B-COS engineers bacteria to produce precise molecules that activate the plant's own immune systems. It's nature-inspired protection with the consistency and cost-effectiveness that farmers actually need.

By 2050, we’ll need to feed nearly 10 billion people while climate change rewrites the rules of farming. For decades, we’ve managed to keep up with growing demand by making synthetic pesticides indispensable to modern agriculture. These pesticides are both effective and reliable, and that consistency matters enormously when farmers and entire food systems depend on predictable harvests.

But the price has been steep. Synthetic pesticides harm beneficial insects, contaminate soil and water systems, and contribute to antimicrobial resistance. They also face mounting regulatory pressures from national governments across Europe and beyond.

Biopesticides, made from natural ingredients, offer an alternative. They can work with nature’s own defense systems, targeting specific pests while leaving beneficial organisms unharmed. They biodegrade quickly and can resist pest adaptation. However, they sometimes fail to work consistently. When a single bad season can mean financial ruin, farmers gravitate toward tools that deliver predictable results, however much they want alternatives.

A question of consistency

The problem traces back to how traditional biopesticides are produced. Take chitosan, one of the most well-known plant immune activators. Companies extract it from insect shells, crustacean waste, or fungal biomass through chemical processes that produce wildly variable mixtures—leading to wildly variable results in the field.

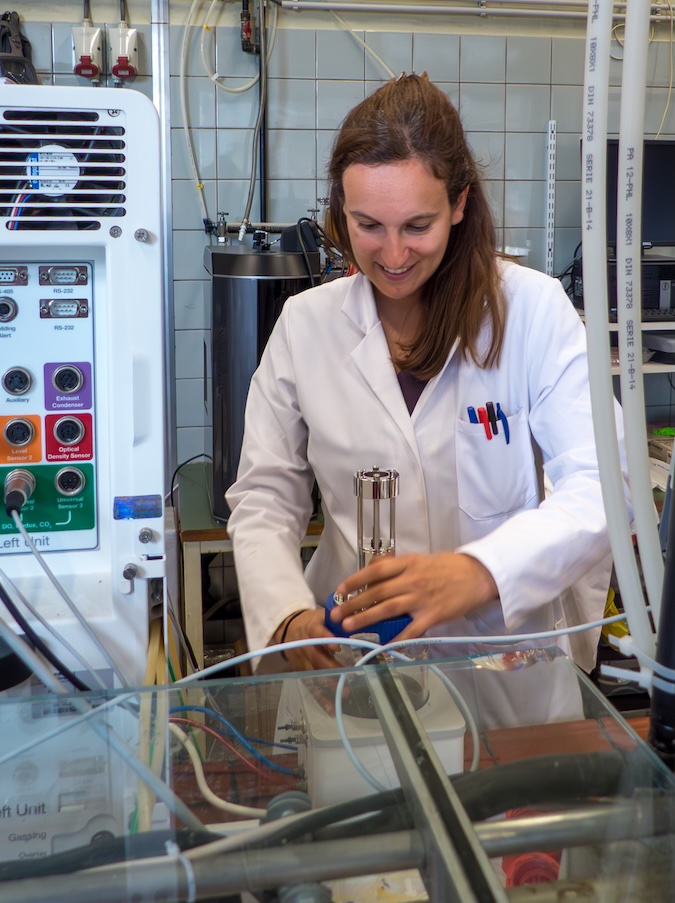

An alternative to this extraction approach is being pioneered by B-COS, a new spin-off from Ghent University. B-COS engineers bacteria to produce chito-oligosaccharides: carbohydrate molecules with similar action as chitosan but with exact, controlled structural specifications. The result is pharmaceutical-grade purity that has eluded the biopesticide industry.

The leap from the lab bench

The technology emerged from over 15 years of work in Prof. Marjan De Mey‘s synthetic biology lab at Ghent University. B-COS Co-founder and CEO, Chiara Guidi, completed her PhD there in 2020, focusing specifically on chito-oligosaccharides. Co-Founder and CTO Wouter Demeester completed his thesis in 2023.

In the years following Guidi’s PhD, she and Demeester continued to work together on the technology and fervently discussed its potential out in the world. Could this technology solve real problems for farmers? Would it be economically viable? “I believe researchers should be involved in commercializing their discoveries to make a real-world difference,” Guidi explains.

When they spun out the company in June 2025, they brought in Maaike Perneel as the third co-founder. Her ag-tech experience filled a critical gap, bringing the commercial agriculture perspective that would be essential for bringing a university technology to market.

The shift from lab to company wasn’t seamless. “The work is challenging. Finance, admin, HR, legal… so many balls in the air beyond science,” Guidi admits. But Demeester adds that the challenge is rewarding: “It’s very nice to work together in a team that has the same vision and goal.”

“I believe researchers should be involved in commercializing their discoveries to make a real-world difference.”

Chiara Guidi, CEO B-COS

Engineering consistency

The B-COS platform works through precision fermentation. While traditional methods extract chitosan from whatever biological material is available, B-COS engineers bacterial cells to produce specific chito-oligosaccharides. The engineered bacteria grow on simple sugar feedstocks in controlled conditions, producing molecules with >95% batch consistency and consistent biological activity, a stark contrast to the heterogeneous mixtures derived from chitosan extraction methods.

What makes the platform particularly powerful is its tunability. The same bacterial system can be adjusted to produce different molecules for different crops and threats. Drought stress in potatoes needs one configuration. Nematode resistance in tomatoes needs another. Production cycles run just 4 to 5 days, and application rates are remarkably low: grams of active ingredient per hectare.

When the moment is right

By mid-2025, as the spinoff became official and the founders were ready to move from university lab to market reality, biotope’s basecamp program came around and it was a perfect match.

Biotope wasn’t a new connection for the founders as they’d known Annick Verween and the biotope team for years, and there had been ongoing discussions about working together. But timing matters. Now that the technology was mature and there was a focus on commercialization, the biotope connection made a lot of sense.

The basecamp program provided exactly what an early-stage company needs: direct, honest feedback on their approach, connections with other founders facing similar challenges, and focused time for the three co-founders to develop their working relationship. Founders from all over the world, from Uruguay, the UK and the United States shared the cohort, providing perspective on how regulations and market realities differ globally, insight that will be crucial as B-COS looks beyond Europe.

“If farmers really use our product, that’s when we know we’ve shown our value.”

Wouter Demeester, CTO B-COS

Earning a place in the field

As a biotope portfolio company, B-COS is moving into the next phase. The year ahead involves raising funding, scaling production, navigating European regulations, and expanding the team beyond the founders. It will also be about refinement, learning from other companies in the portfolio, sharpening their market positioning, and staying open to pivoting the business model as they learn more about what works.

The long-term vision is to become a trusted name in crop protection that proves its value through farmer adoption. Their products are designed to work alongside existing synthetic pesticides and other biocontrol agents, creating complementary effects rather than requiring an either-or choice. The initial focus is potatoes and tomatoes, high-value crops where drought and, in tomatoes’ case, nematodes create relentless pressure.

“If farmers really use our product, that’s when we know we’ve shown our value,” Demeester says. For a technology built on consistency and reliability, farmer adoption is the ultimate validation.

More News

The fundraising mirage

Typcal is brewing the future of pragmatic protein

AmphiStar secures €12.5m EIC funding

biotope recap: Summer edition

Annick Verween on the VCo2 podcast

2024 wrapped

Networking with cohort six

B’ZEOS celebrates seed round milestone

Tackling food waste at its source

The value of good mentors

Meet our Spring ‘24 cohort

His son’s allergy turned this father into a founder

FlyBlast: on a mission to solve meat

Biosurfactants from food waste? Meet AmphiStar

Probitat interview

B’ZEOS: sustainable packaging made of seaweed

Elogium: Poultry probiotics for safer food

Launch of Biotope ventures fund

Bolder Foods: non-dairy cheese for a better world

BioVox article

Have you got what it takes?

- Pressure-test your biotech with expert feedback

- Align your team and sharpen your strategy

- Turn your startup into an investment-ready business